PRODUCTS - End Forming Systems

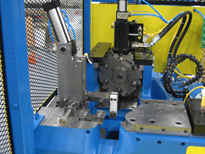

Model M71-H-6 Tube End Forming System

The Manchester model M71-H-6 is a hydraulically operated machine that uses a programmable six position rotary tool holder. The machine is easily programmed to make one through six strokes and a simple adjustment determines the length of the return stroke for improved cycle times. The rotary tool holder allows for the use of larger spring loaded punches required for many of today's end form requirements. See the video!

Standard Equipment

Size: 44"W x 82"L x 76"H

Weight: 5,200 lbs

- Cycle Time: 2.4 to 15 seconds*

- Tube O.D. Capacity: 1.5"

- Maximum Jaw Opening: 1.75"

- Ram Cylinder: 3-1/4" bore x 6" stroke

- Ram Force: 15 tons (maximum)

- Clamp Cylinder: 2-1/2" bore x 2-1/2" stroke

- Clamp Force: 17-1/2 tons (maximum)

- Hydraulic Unit: 15HP 21 GPM

- Working Pressure: 1200 PSI

- Maximum Pressure: 2500 PSI

- H.M.I. Interface

- Part Present Sensor

- Air Required: 60 to 80 PSI & 3 CFM

- Electrical Required: 480 VAC/3 Phase/60 Hz

- 12 Month Warranty on Machines

* Cycle time depends on the application and optional equipment.

Valuable Options

- Larger Hydraulic Unit & Larger Ram Cylinders

- Autoload & Unload Systems

- Custom Cycle Start Initiators

- Light Curtains

- Custom Painting

Advanced Features

- Programmable 1 to 6 Stroke and Double index Capability

- Easy Access for Tooling Changeovers and Services

- Compact Footprint