PRODUCTS - End Forming Systems

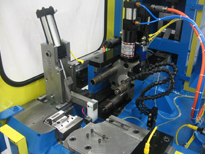

Model M71-E-3 & M71-E-6 Electric Tube End Forming Systems

The M71-E-3 & M71-E-6 Electric Tube End Forming Machines accept tubes up to 1-1/2" in diameter. The M71-E-6 has a servo driven, six position rotary shuttle and the M71-E-3 has a pneumatically driven, three position shuttle. These are easily programmable through the machine’s H.M.I. (Human Machine Interface). The ram is servo driven through a mechanical

linkage system and also allows for independent stroke speed adjustment. The clamp system is a pneumatic linkage system. These machines accept the same tooling as the M71-H-3 and M71-H-6 machines. Also included in these machines are a servo flag stop system which allows for quick, tool free flag adjustments. This helps customers achieve quicker and more accurate setups. These machines also provide easy access for tooling changeovers and service, energy savings, and noise reduction.

Standard Equipment

Size: 44"W x 88"L x 99"H

Weight: 5,200 lbs

- M71-E-3 Cycle Time: 2.4 to 4.5 seconds*

- M71-E-6 Cycle Time: 2.4 to 8.5 seconds*

- Tube O.D. Capacity: 1.5" (38mm)

- Maximum Jaw Opening: 1.75"

- Ram System: Servo Driven Toggle with 6" of stroke

- Clamp System: Pneumatically Driven Toggle with 8" Bore Cylinder

- Part Present Sensor

- H.M.I. Interface

- M71-E-3 Tooling Stack-up: 8.640"

- M71-E-6 Tooling Stack-up: 10.640"

- Air Required: 95 PSI, 4-5 CFM

- Electrical Required: 480 VAC/3 Phase/60 Hz

- 12 Month Warranty on Machines

* Cycle time depends on the application.

Valuable Options

- Special Voltages

- Light Curtains

- Custom Painting

- Autoload & Unload Systems

- C.E. Certification

Advanced Features

- Independent Stroke Speed Adjustment

- Programmability of Strokes

- Easy Access for Tooling Changeover/Service

- Compact Footprint